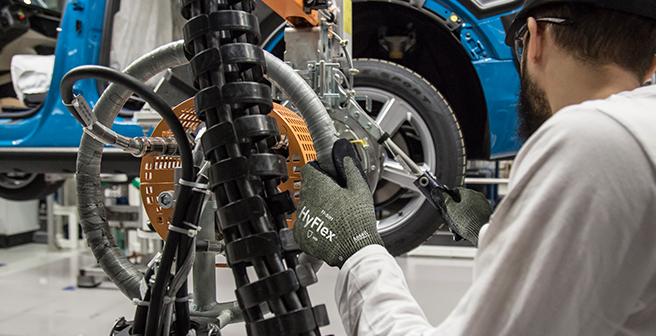

AnsellGUARDIAN®

The most appropriate PPE solutions to protect against hazards will vary based on each individual company’s unique set of needs, applications and processes. AnsellGUARDIAN® is our consultative service to help companies select and implement the right PPE solutions to improve safety, increase productivity software systems and leverage a database of over 30,000 chemicals. We have implemented PPE recommendations in over 15,000 facilities worldwide, reducing injuries and saving companies a total of $165M.

There is no cost for an AnsellGUARDIAN® assessment. Request an assessment now.

.ashx?rev=ba3f0783fe7d42bcb6f233aedb371bab&mw=320&hash=C3F224A4AFC381C51375E448D9D5072A)